Precision Machine Shop in Massachusetts

Are you searching for a precision machine shop in Massachusetts? Reach out to our team of experienced professionals at P&L Machine. For over four decades, we have been raising the bar for quality and consistency in the machining space. Insights gained from our years of experience are applied to every project we undertake. Our state-of-the art facility features the latest technology and we’re ISO 9001:2015 certified. We’re proud to work with companies in industries that demand flawless results – such as aerospace, energy, defense and biotechnology. You can count on us to handle your project with the utmost care and precision, from start to finish.

Call or email us to begin exploring options for your project with a member of our team.

Where Innovation Meets Excellence

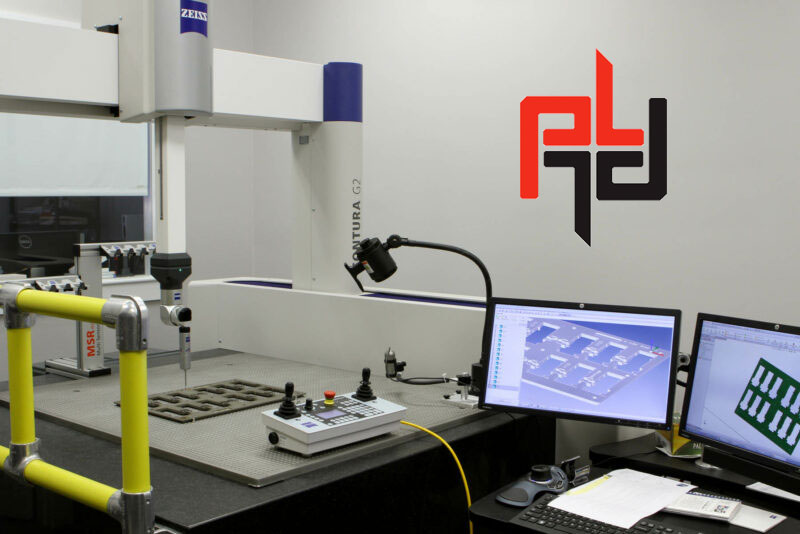

At P&L Machine, our unmatched expertise and cutting-edge equipment helps set us apart as the best precision machine shop in Massachusetts and throughout the United States. We use industry-leading software like MasterCam, SolidWorks and Vericut to operate a diverse array of high-end CNC mills and lathes. One machine worth noting is our Mazak HCN5000 4 Axis Horizontal Machining Center, which uses a 18,000 rpm spindle to articulate complex features. We also use our Fanuc Robodrill series, with DDR 4th axis trunnion table, for other detailed milling applications. When it comes to turning, our Nakamura Tome AS200, Hardinge Talent 8/52-SV and Feeler FTC-200L Turning Center exemplify exceptional accuracy and flexibility. For quality control, our Zeiss CMM Contura G2 and RAM Optical Starlite 150 Vision System are indispensable.

Seamless Manufacturing: Custom Plans, Quality Results

Clear communication and individualized support are the hallmarks of our approach to precision machining. We work with you to create a manufacturing plan that meets your specifications and deadlines. From there, we leverage our experience and equipment to transform your ideas into precision components with speed and efficiency. Our range of services spans from prototype development to extensive lights-out manufacturing. We ensure quality results with our detailed QA process including automated measurements and visual inspections. A detailed report comprised of historical and statistical process control data can also be provided for your records. Our goal is to surpass your expectations and establish a long-term partnership by consistently providing your components on schedule, within budget, and according to all specified requirements.

Reach out to our team to get started today. Call us at 978-486-9626, email info@plmachine.com or send us a message through the form here on our website.

CNC Turning Services

CNC Milling Services