Medical Instrument Manufacturing Company

In the rapidly evolving healthcare space, there is always room for new innovative products. At P&L Machine, we help companies in this space take their projects to the next level as their trusted third-party production partner. Our ability to consistently deliver flawless results has helped position us as the go-to medical instrument manufacturing company for businesses in Massachusetts, throughout New England and across the United States. We proudly work with clients in every phase of the process – from creating your first prototype to bringing your surgical instruments, test lab equipment or other devices to market with lights out production runs, subassembly service and more.

Call or email us to begin exploring options for your project with a member of our team.

Where Healthcare Meets High-Tech

Our status as the top medical instrument manufacturing company is rooted in our exceptional adaptability. We seamlessly bring concepts of every size and level of technical complexity to completion through the application of our extensive expertise, cutting-edge machinery and high-quality materials. This versatility is reflected in our dynamic portfolio, which features microscale components as well as full-size medical parts and complete builds. Medical-grade metals, like titanium, stainless steel and nitinol as well as plastics, ceramics, composites and polymers all fall within the purview of our diverse CNC machining abilities. We also use effective enterprise resource planning (ERP) software so that you can scale your output as needed.

Engineered for Excellence

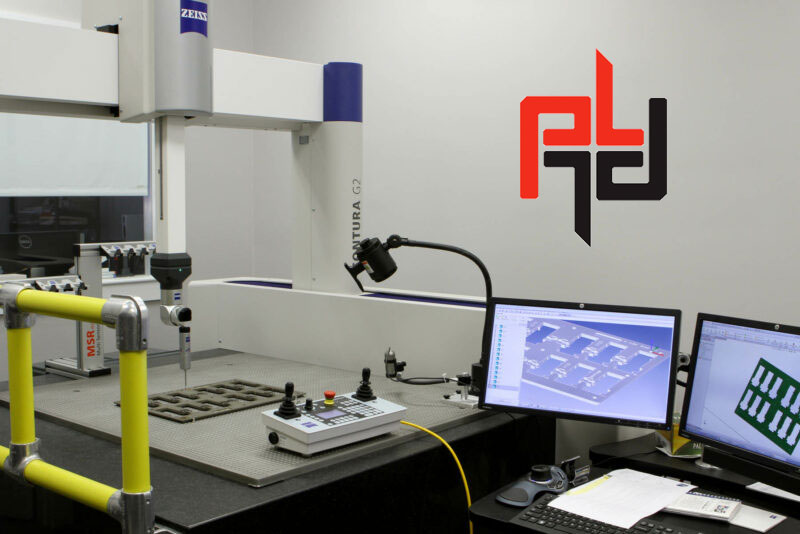

At the core of our medical instrument manufacturing company is a powerful lineup of CNC milling and drilling equipment. Among these machines, a few worth highlighting include the Nakamura Tome AS-200, equipped with a 12-position turret and live tooling capacity, and the Mazak HCN5000, which features an 18,000 rpm high-speed spindle and 4-axis capability. Because there is no room for error in medical manufacturing, we implement strict quality control measures. This includes conducting thorough CMM inspections with our Zeiss CMM Contura G2 and RAM Optical Starlite 150 Vision System. Our commitment to quality and compliance is further reflected in our ISO 9001:2015 certification.

Call (978) 486-9626 or email info@plmachine.com to get started on your project with the premier medical instrument manufacturing company.

CNC Turning Services

CNC Milling Services