Medical Equipment Machine Shop in Massachusetts

In healthcare applications, even the slightest error can have potentially life-threatening consequences. As such, every component used for medical instruments and devices must be flawlessly designed and manufactured. At P&L Machine, we take pride in delivering precision medical equipment production solutions for professionals throughout the Commonwealth. Whether you have a biotech startup in Cambridge’s Kendall Square, a collegiate research group in Western Mass, or any kind of organization in-between – we are the ideal medical equipment machine shop in Massachusetts for your project. From prototyping and trial runs to complete lights out production with subassembly – our approach is truly full-service.

Call or email us to begin exploring options for your project with a member of our team.

Crafting Tomorrow’s Technology

If you are searching for a medical equipment machine shop in Massachusetts with the skills and resources to deliver consistent quality, accuracy and performance, look no further. Our team of professionals apply their years of specialized training and hands-on experience to tackle builds of every size and level of technical sophistication – using cutting edge equipment and premium materials. Just a few examples of items we can manufacture that illustrate our versatility include microscale components as well as full-sized housing for diagnostic instruments, surgical tools and more. We work with metals like titanium, stainless steel and nitinol as well as plastics, ceramics, composites, polymers and other materials commonly used in the medical device space. Our strategic use of enterprise resource planning (ERP) software ensures the scalability of your project.

The Perfect Tool for Every Task

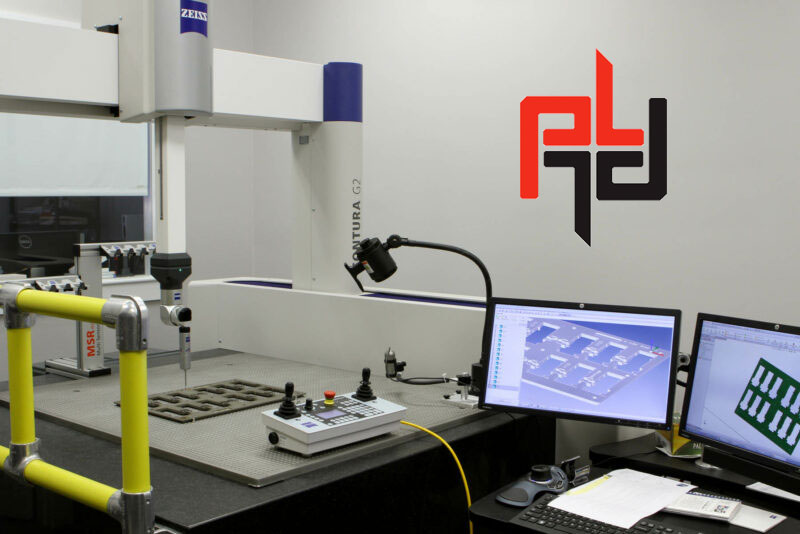

The powerful lineup of CNC milling and drilling equipment at our Littleton medical equipment machine shop in Massachusetts is integral to our success. Noteworthy examples include the Nakamura Tome AS-200, equipped with a 12-position turret and live tooling, and the Mazak HCN5000, with its 18,000 rpm high-speed spindle and 4-axis functionality. To maintain precision in medical equipment manufacturing, we enforce rigorous quality control measures. We use Zeiss CMM Contura G2 and RAM Optical Starlite 150 Vision Systems to conduct comprehensive CMM inspections. Our ISO 9001:2015 certification further underscores our commitment to quality and compliance.

Call (978) 486-9626 or email info@plmachine.com to get started on your project with the premier medical equipment machine shop in Massachusetts today.

CNC Turning Services

CNC Milling Services