Machine Shop Serving Rhode Island

When it comes to selecting a machine shop serving Rhode Island, consistent delivery and expertise matter. That is why manufacturing companies, engineers, purchasing agents and others choose our team at P&L Machine. You can count on our seasoned professionals to realize every aspect of your design. We fabricate complex components with the utmost precision using the latest milling and turning equipment in our state-of-the-art facility located in neighboring Massachusetts. Take confidence in our ISO 9001:2015 certification status and over four decades of experience. Just a few of the closely regulated industries that we proudly serve include the medical and biotech industry, energy and electrical industry, as well as aerospace, military and defense industries.

Call or email us to begin exploring options for your project with a member of our team.

Empowering Your Project

No matter what you have in mind for your design, we have the skills and resources to make it happen. We use advanced CNC mills and lathes, supported by critical software like MasterCam, SolidWorks and Vericut. Milling machines in our fleet include the Mazak HCN5000 4 Axis Horizontal Machining Center, Hardinge Talent 8/52-SV, Fanuc Robodrill A-D21MiB5 and Kitamura MyCenter 4XiD Machining Center. Versatility and precision are defining characteristics of these systems. Our technical capabilities are further enhanced with our Nakamura Tome AS200, Feeler FTC-200L Turning Center and Hardinge Talent 8/52 – SV Turning Center.

Comprehensive Manufacturing Solutions

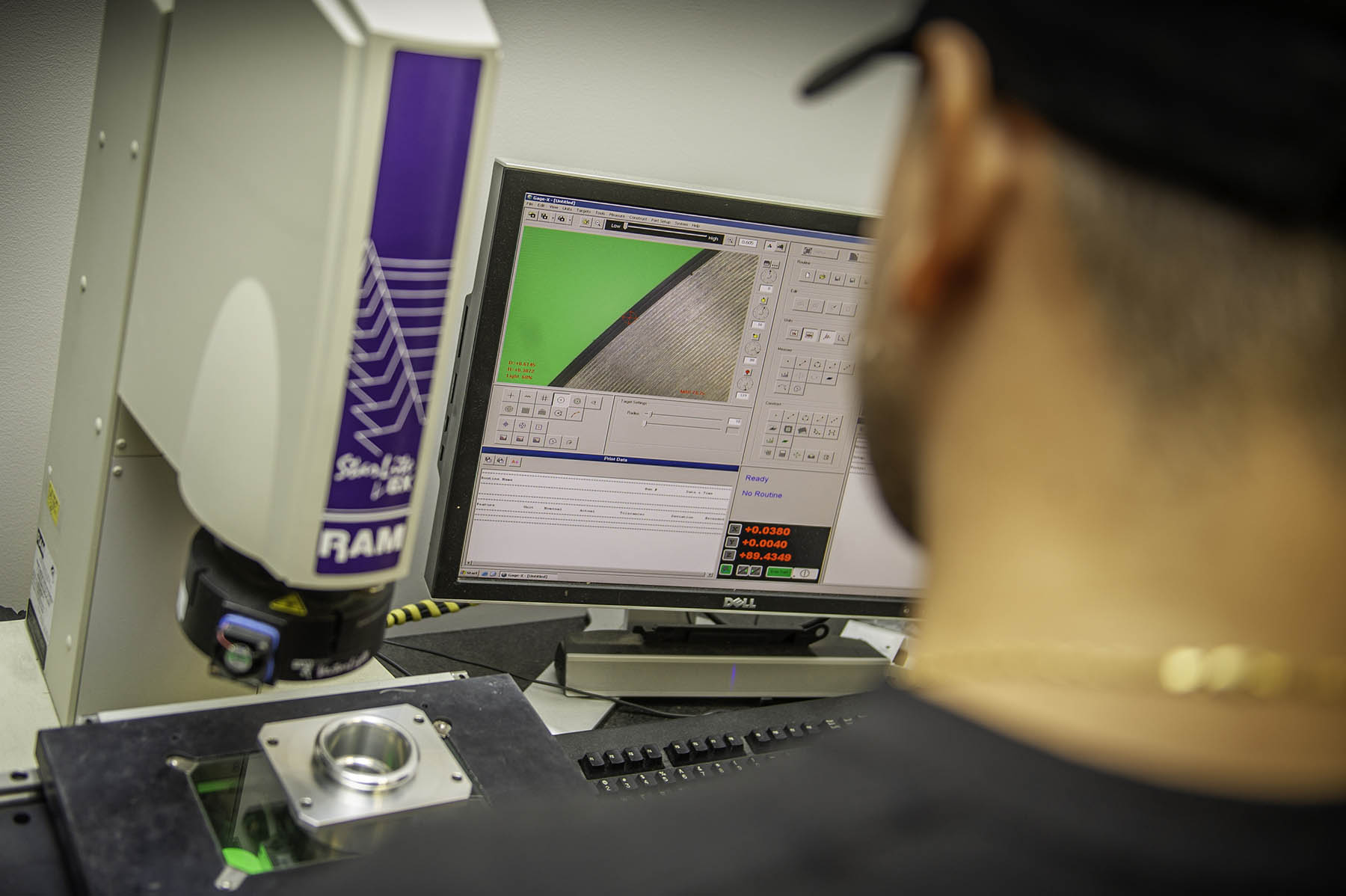

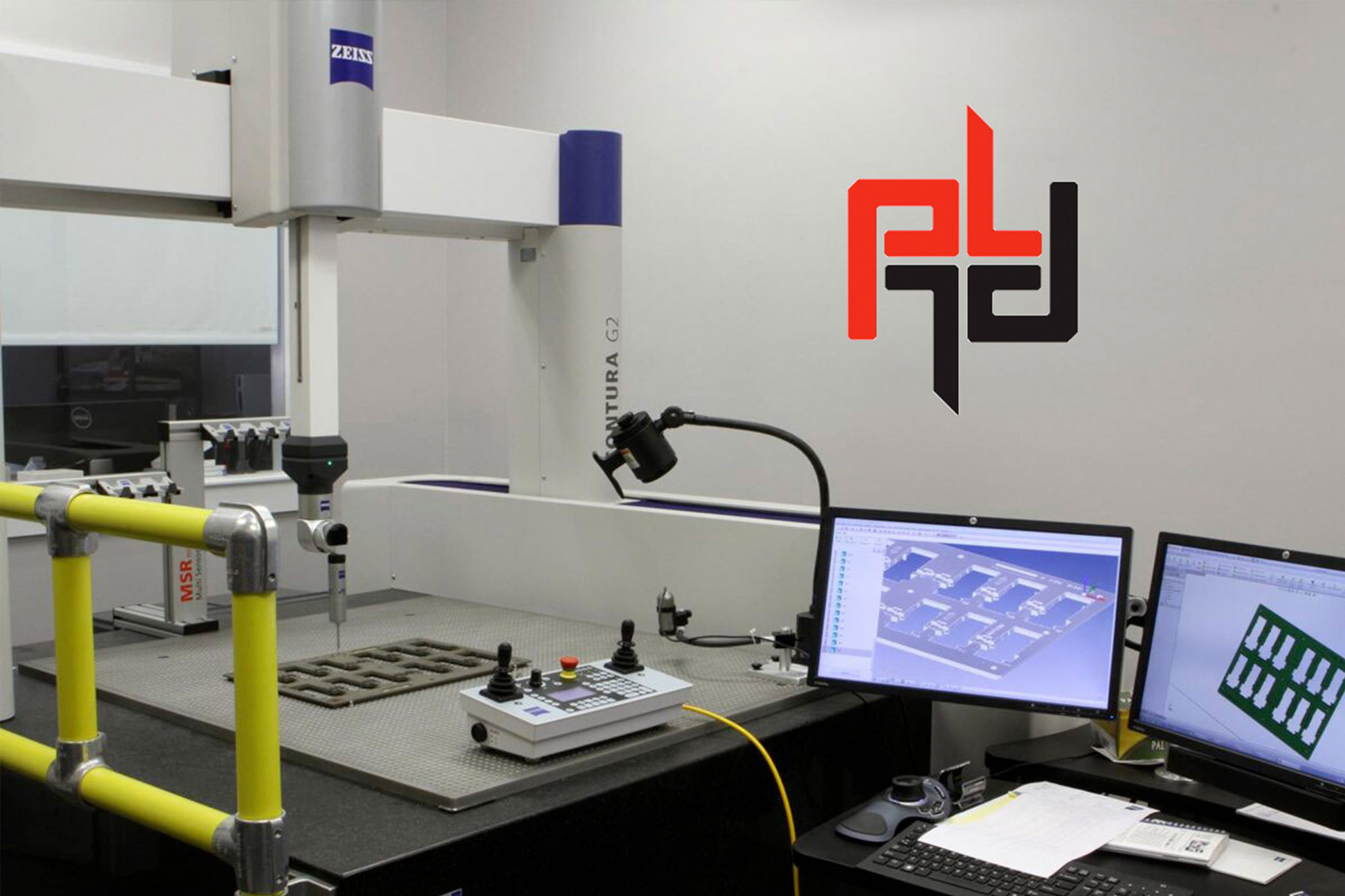

We take pride in our ability to execute diverse precision machining projects for companies across Rhode Island. We proudly offer initial prototyping, 3D printing and short runs as well as full lights-out manufacturing, sub-assembly and everything in-between. Strict quality control methods and proven techniques ensure high quality results that are in line with compliance standards. This encompasses visual checks and in-depth review of data reports as well as CMM inspection using our Zeiss Contura G2 and RAM Optical Starlite 150 Vision System.

Get Started Today!

Give us a call at 978-486-9626, email info@plmachine.com or send us a message through the form on our website to get started on your manufacturing project.

Cutting Edge Tools and Technology of the Trade

Our ever-growing and expanding collection of specialized technology and equipment allows us to effectively meet every aspect of your unique requests.

Precision CNC Turning Machining Services

If your project requires rotational symmetry, the most cost and time effective way to produce it is likely through our CNC turning capabilities. Bolts, screws, pins and other cylindrical components are perfect for this machining technique. CNC turning is facilitated with preprogramed CNC lathes. Because this equipment is less complex than CNC milling systems with multiple axis — it can often be utilized at a lower expense.

Features of our precision CNC turning machining services include:

Precision Horizontal Milling Services

Creating more intricate parts can be affectively accomplished with our horizontal CNC milling machines. These systems perform material reduction on multiple axis with exceptional precision. Our collection of CNC equipment includes both 3 axis and 4 axis milling machines.

Features of our precision CNC turning machining services include:

“Integrity of product and performance is the key to their success and has become the standard against which we gauge all others.”

“We greatly value our relationship with P&L Machine. You are our GO-TO vendor when we have a tough or timely issue to deal with. We appreciate your willingness to work with us.”

“P&L is easy to deal with and delivers good quality work all the time.”

“I really enjoy doing business with P&L.”