Machine Shop in New Hampshire

When New Hampshire organizations have a project that requires a machine shop, they place their trust in the capable hands of our team at P&L Machine. With an extensive track record spanning over four decades, we have honed our expertise in serving companies that operate in highly regulated industries, including aerospace, energy, defense and biotechnology. Our cutting-edge facility in Littleton, Massachusetts is ISO 9001:2015 certified and equipped with state-of-the-art milling and lathe machinery, indispensable tools for crafting high-precision components. So, no matter what your project entails, you count on us to articulate your vision with precision.

Call or email us to begin exploring options for your project with a member of our team.

Excellence in Every Detail

There’s no other machine shop in New England that rivals the expertise and capabilities of P&L Machine. We’ve equipped our cutting-edge facility with a diverse range of top-of-the-line CNC mills and lathes as well as MasterCam, SolidWorks and Vericut to maximize efficiency. For instance, our Mazak HCN5000 4 Axis Horizontal Machining Center features a 18,000 rpm spindle that is exceptionally capable of intricate detail. Another notable machine is our Fanuc Robodrill series, with DDR 4th axis trunnion table. Additionally, our Nakamura Tome AS200, Hardinge Talent 8/52-SV and the Feeler FTC-200L Turning Center, are both known for their exceptional accuracy and flexibility.

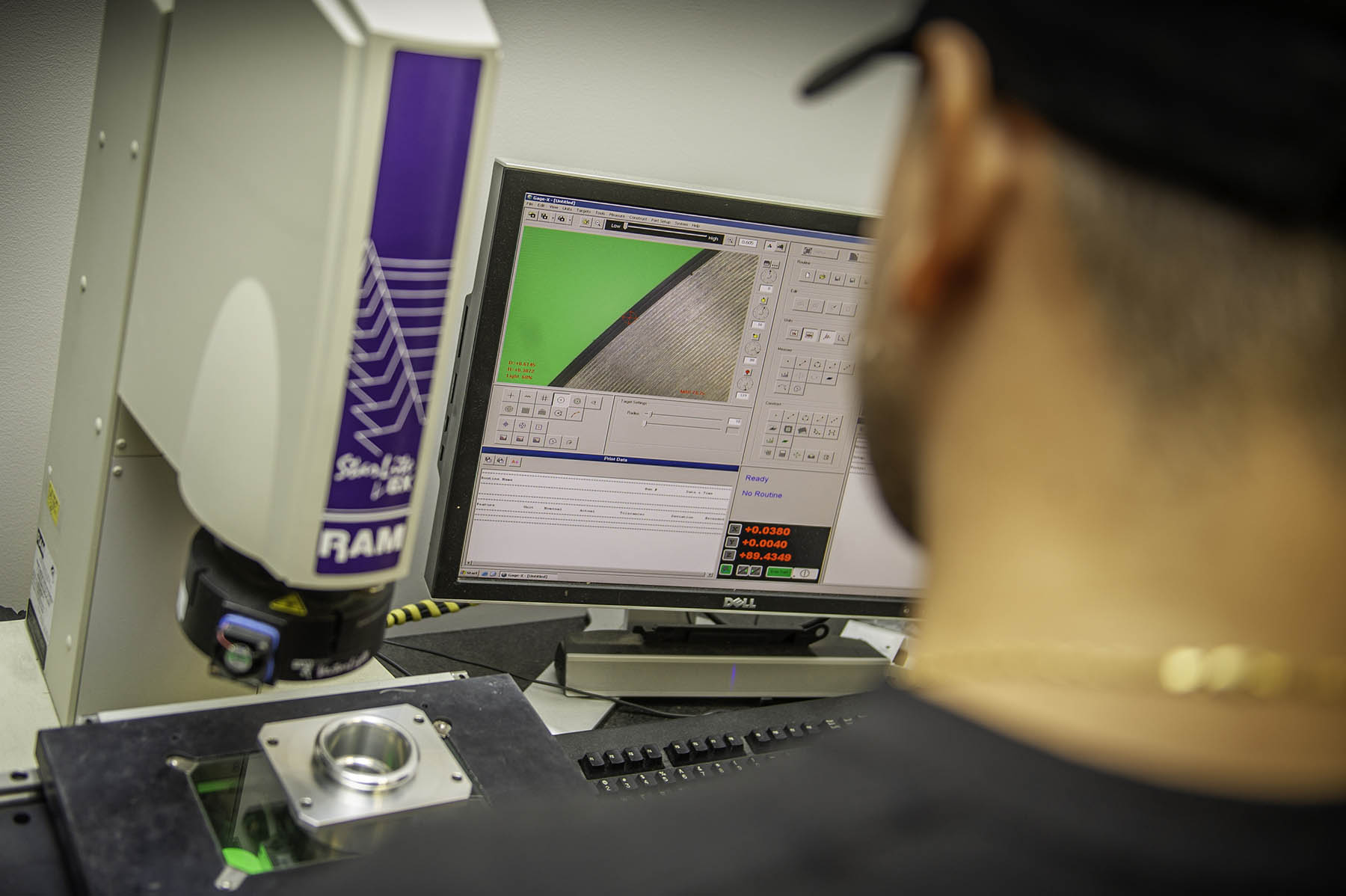

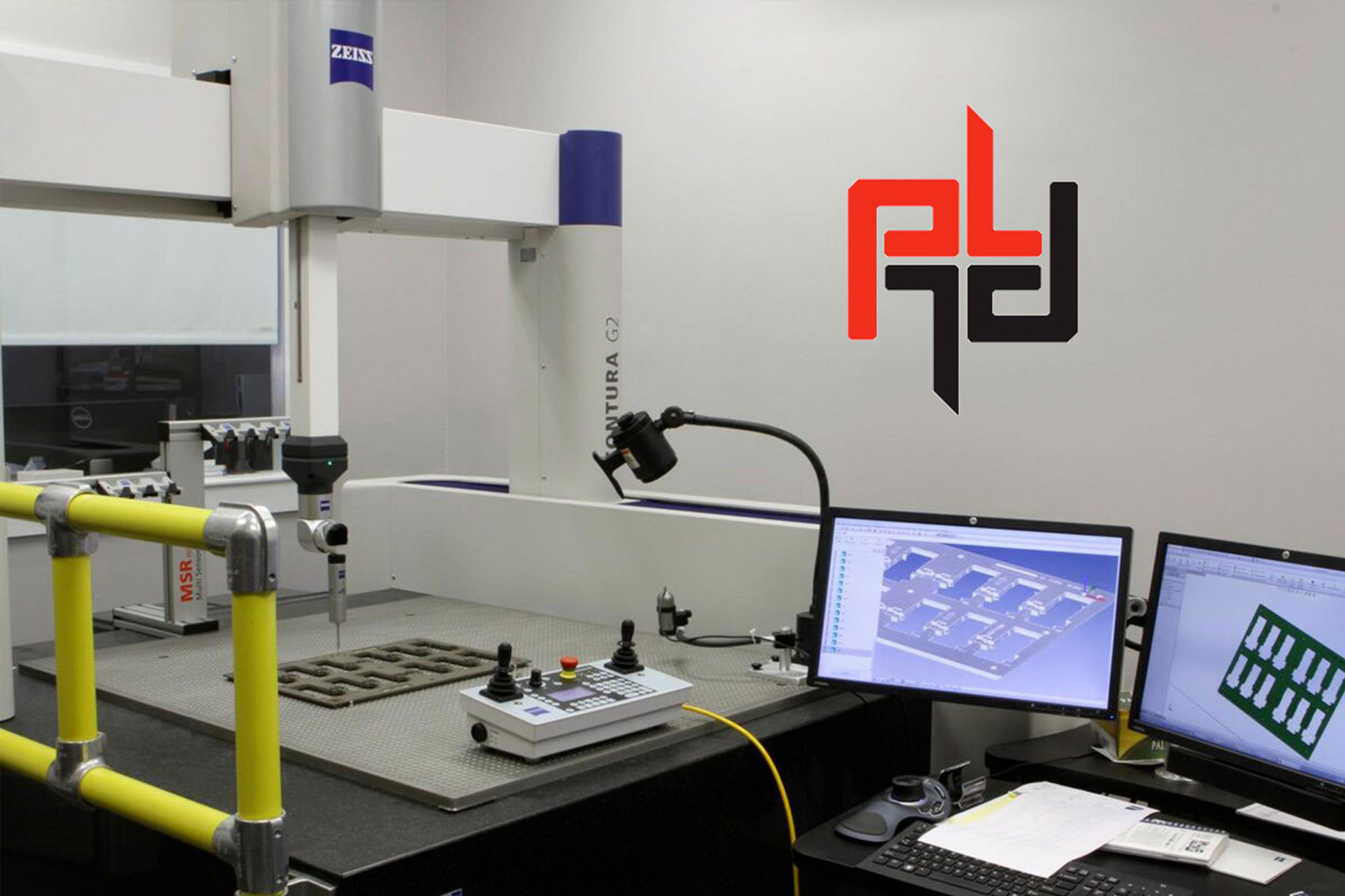

Consistent Quality, One Component at a Time

From initial prototyping and short-runs to lights-out production with sub-assembly services and more – we are committed to delivering flawless outcomes for projects of all sizes, technical complexity and logistical constraints. Precision and compliance are our top priorities. Our components will always meet your exact specifications and industry standards. Our quality process is a combination of visual checks and automated measurement as well as analysis of data reports and historical data. For CMM inspection, we use advanced equipment like the Zeiss Contura G2 and RAM Optical Starlite 150 Vision System.

Our team is ready to help you with your machining project. Call us at 978-486-9626, email info@plmachine.com or send us a message through the form here on our website to get started.

Cutting Edge Tools and Technology of the Trade

Our ever-growing and expanding collection of specialized technology and equipment allows us to effectively meet every aspect of your unique requests.

Precision CNC Turning Machining Services

If your project requires rotational symmetry, the most cost and time effective way to produce it is likely through our CNC turning capabilities. Bolts, screws, pins and other cylindrical components are perfect for this machining technique. CNC turning is facilitated with preprogramed CNC lathes. Because this equipment is less complex than CNC milling systems with multiple axis — it can often be utilized at a lower expense.

Features of our precision CNC turning machining services include:

Precision Horizontal Milling Services

Creating more intricate parts can be affectively accomplished with our horizontal CNC milling machines. These systems perform material reduction on multiple axis with exceptional precision. Our collection of CNC equipment includes both 3 axis and 4 axis milling machines.

Features of our precision CNC turning machining services include:

“Integrity of product and performance is the key to their success and has become the standard against which we gauge all others.”

“We greatly value our relationship with P&L Machine. You are our GO-TO vendor when we have a tough or timely issue to deal with. We appreciate your willingness to work with us.”

“P&L is easy to deal with and delivers good quality work all the time.”

“I really enjoy doing business with P&L.”