Machine Shop in Massachusetts

If you are searching for a Machine Shop in Massachusetts, look no further. At P&L Machine we have over 40 years of precision machining experience. Our state-of-the-art facility is ISO 9001:2015 certified and equipped with the cutting-edge mills and lathes that are essential for producing high-precision components. The expertise of our team extends across diverse industries in which accuracy and quality are paramount. Aerospace, energy, defense and biotechnology companies are just a few examples of the organizations that we proudly serve. You can count on us to take your project from concept to completion with the utmost attention to detail and care.

Call or email us to begin exploring options for your project with a member of our team.

Your Vision, Our Precision

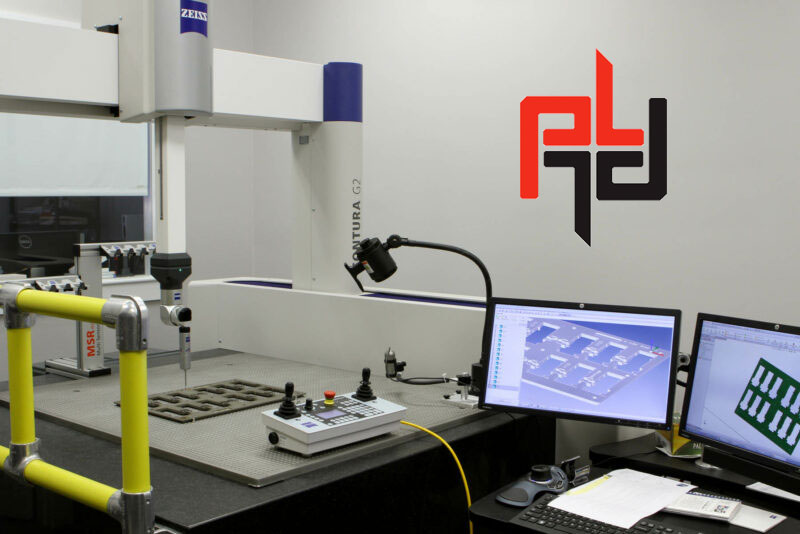

You won’t find another machine shop in Massachusetts, New Hampshire, Connecticut or elsewhere in the region that is more capable than our team at P&L Machine. Our facility is outfitted with a diverse range of high-end CNC mills and lathes, alongside advanced software like SolidWorks, MasterCam, and Vericut. Key equipment includes the Mazak HCN5000 4 Axis Horizontal Machining Center producing precision in complex projects and capable of light-out operations, and the Fanuc Robodrill series, which features a DDR 4th axis trunnion table. For turning, we have a Nakamura-Tome AS-200 as well as a Feeler FTC-200L Turning Center for exceptional accuracy and flexibility. Our Zeiss CMM Contura G2 and RAM Optical Starlite 150 Vision System ensure accuracy and consistency.

From Concept to Compliance and Beyond

At P&L Machine, our approach to design and manufacturing is founded on clear communication and tailored support. Combined with our advanced capabilities and state-of-the-art equipment, this guarantees that we can efficiently and cost-effectively transform intricate ideas into concrete components . Whether you need a prototype, short-run or full-scale lights-out production – we are the here to ensure that each piece meets your exact specifications and applicable compliance standards. Our quality assurance process features both automated measurement and visual inspection. This meticulous approach also encompasses creating detailed data reports as well as accessing historical and statistical process control data, so you can rest easy knowing that your custom CNC machining project is perfectly fabricated.

CNC Turning Services

CNC Milling Services