Machine Shop for the Energy and Electrical Industry in Massachusetts

From charging up your cellphone, laptop and other digital devices to lighting, heating and cooling your home or business – we owe much of our modern lifestyle to a dependable power grid. These comforts and essentials would not be possible without reliable power plants, substations, transmission lines and other energy infrastructure built from quality components. Manufacturing CNC machined parts for such applications is a specialty of ours at P&L Machining. When local businesses need a machine shop for the energy and electrical industry in Massachusetts, they rely us. We take pride in serving a diverse clientele that encompasses oil, gas and other legacy fuels as well as wind, solar, hydro and other renewables.

Call or email us to begin exploring options for your project with a member of our team.

Sparking Your Innovation

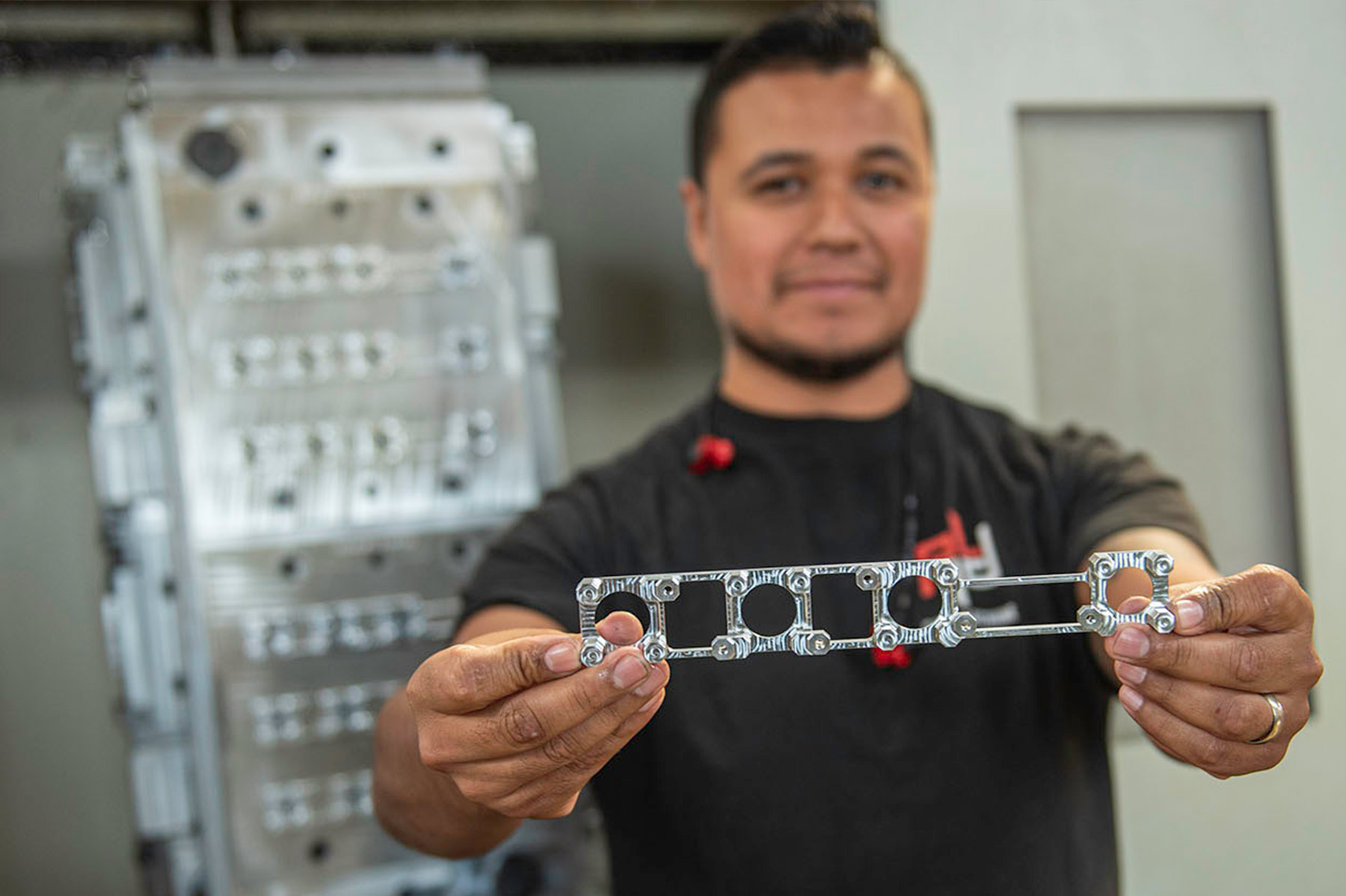

Whether you are still in the prototyping phase or are ready for lights out production with subassembly services, we are the ideal machine shop in Massachusetts for the energy and electrical industry. Just a small sample of the kinds of components we can create for you include large parts turbine blades, pipeline parts, heavy-duty generators as well as tiny pieces or circuit boards, micro connectors and terminals. No matter what material you have in mind for your project, we have you covered. We CNC machine parts from metals, plastics and ceramics as well as specialty composites and alloys with precision. Thanks to our ERP system, we are able to maintain optimal inventory levels, so that your project’s scalability is never compromised.

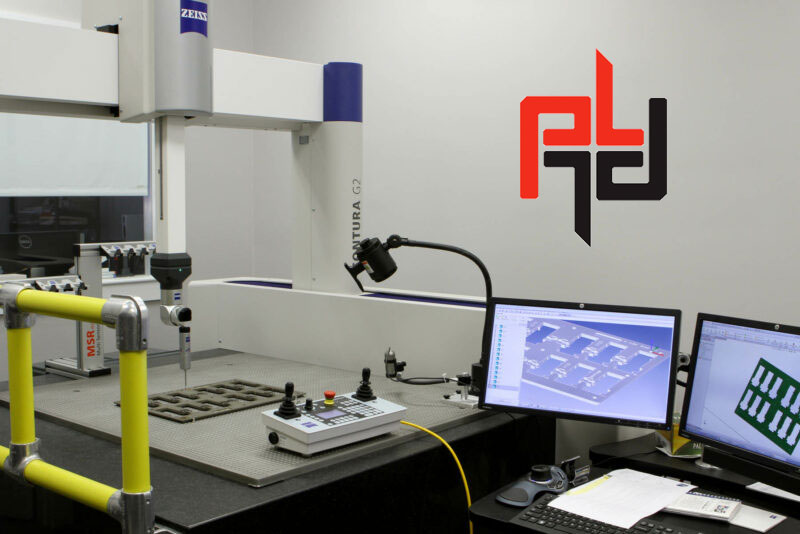

Tech-Driven Precision

Imperfections is not an option when it comes to machining solutions for the energy and electrical sectors. Our Littleton, Massachusetts machine shop is outfitted with an impressive lineup of cutting-edge technology to consistently deliver ultra-precise results. A key instrument in our turning operations is the Nakamure Tome AS-200 which can be live tooled and has a 12-position turret. In the milling department, our Mazak HCN5000 boasts a 18,000 rpm spindle and Renishaw machine tool probe. Our shop is 9001 certified. For quality control, we use the Zeiss CMM Contura G2 and RAM Optical Starlite 150 Vision system to perform meticulous CMM inspections.

Call (978) 486-9626 or email info@plmachine.com to start working with the premier machine shop for the energy and electrical industry in Massachusetts.

CNC Turning Services

CNC Milling Services