Machine Shop for the Energy and Electrical Industry

Almost every aspect of modern life depends on energy infrastructure. The performance of power plants, substations, transmission lines and other equipment that make this modern miracle possible is dependent on the quality of their components. This is where P&L Machine comes in. We have positioned ourselves as the go-to machine shop for the energy and electrical industry by consistently delivering accurate and high-quality results. We proudly serve clients in Massachusetts, throughout New England and across the USA that specialize in legacy fuels like oil and gas as well as renewables like wind, solar, hydro and more.

Call or email us to begin exploring options for your project with a member of our team.

Powering Innovations in the Energy Sector

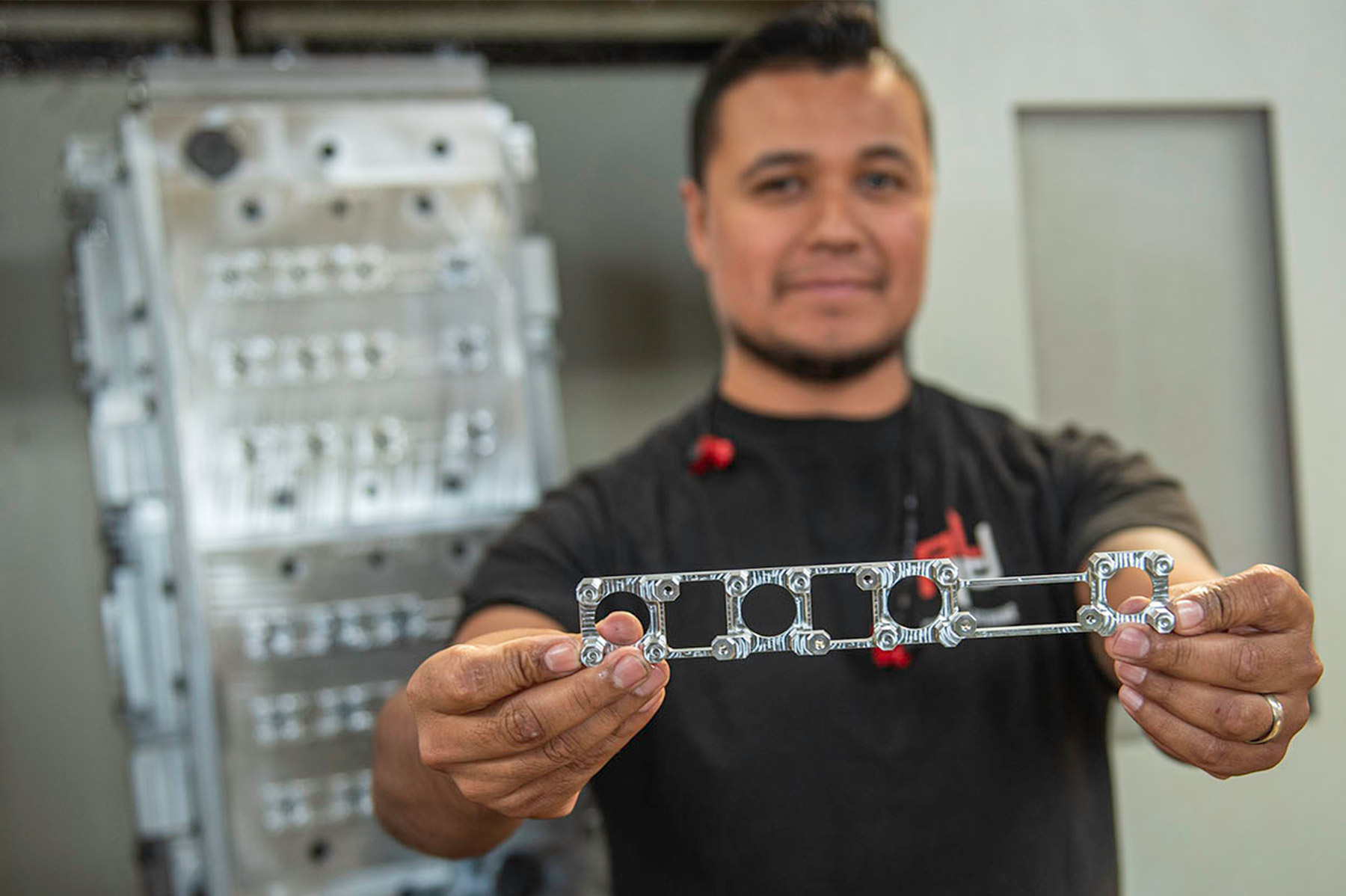

No matter the size or technical intricacy of your project, we are the best machine shop for your energy or electrical company’s needs. You can count on us to create microscale pieces for circuit boards, micro connectors and terminals as well as large components for turbine blades, pipeline parts, heavy-duty generators and more. We have extensive experience working with metals, plastics, ceramics, composites, specialty alloys and other materials commonly used in energy applications. Additionally, our ERP system ensures we always have enough inventory, so you won’t have to worry about scaling.

Elite Craftsmanship and Quality Control

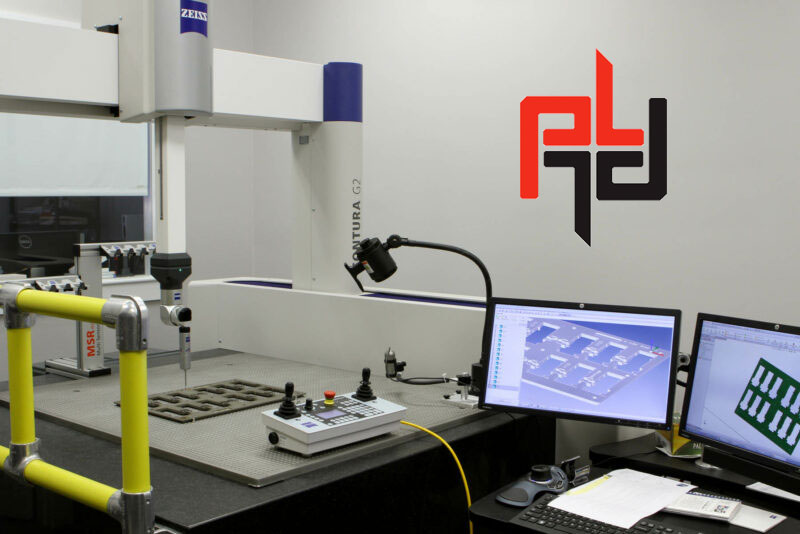

We understand that in the energy and electrical industry, there is simply no room for error. Our team of skilled technicians uses cutting-edge equipment to maintain the tight tolerances required for your products to function safely and efficiently. For example, one of the machines we use for turning is our Nakamura Tome AS-200, which features live tooling capabilities and a 12-position turret. A standout piece of equipment for milling is our Mazak HCN5000, 4 Axis Horizontal Machining Center, with its powerful 18,000 rpm spindle. For quality control, we perform CMM inspections using Zeiss CMM Contura G2 and RAM Optical Starlite 150 vision systems. Our ISO 9001:2015 certification highlights our commitment to best practices and regulatory compliance.

Call (978) 486- 9626 or email info@plmachine.com to start working with the premier machine shop for the energy and electrical industry.

CNC Turning Services

CNC Milling Services