Machine Shop for the Biotech and Medical Device Industry in Massachusetts

Massachusetts is home to some of the country’s most prestigious universities, research institutions, biotech firms and medical device manufacturers. These organizations depend on precision CNC machining to keep their operations running smoothly with custom components for their specialized equipment. That is exactly what we offer at P&L Machine. Our expertise in achieving micron-level accuracy ensures the functionality and reliability of products used in testing, operating rooms as well as other critical medical and scientific settings. The consistency and quality of our work has helped position us as the go-to machine shop for the biotech and medical device industry in Massachusetts – from Boston and Cambridge to the Berkshires, Worcester and everywhere in between.

Call or email us to begin exploring options for your project with a member of our team.

From Blueprints to Breakthroughs

We take on projects of any size and complexity with unmatched precision – from tiny parts for surgical instruments to large-scale components for diagnostic equipment and more. This is made possible through the talent of our team combined with the advanced machinery at our Massachusetts machine shop. Whether you want to construct your product from medical-grade metals, plastics, ceramics, composites or polymers – we have you covered. Scaling your product is simple too. We use both Kanban and consignment methods of inventory management. Our enterprise resource planning (ERP) software ensures that your items are in stock when needed.

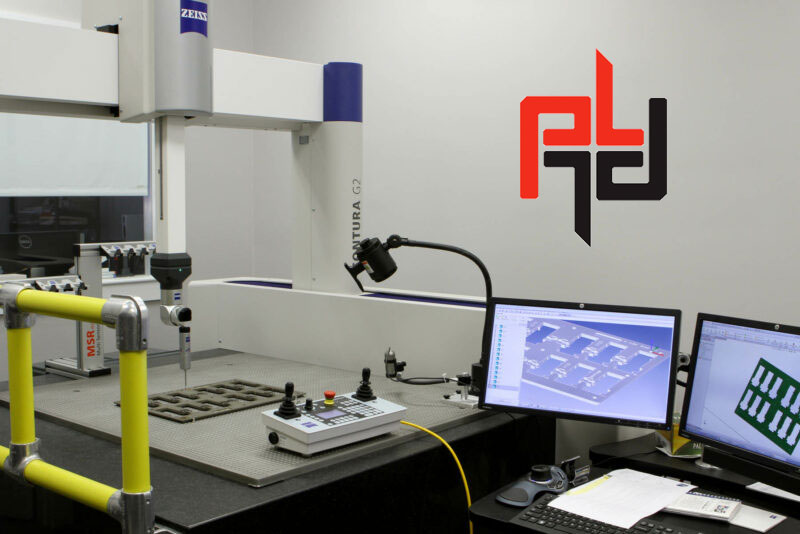

Precise and Compliant Machining Solutions

Our Littleton, Massachusetts machine shop is equipped with state-of-the-art CNC milling and turning centers, essential for serving the local biotech and medical device companies. A few key machines in our lineup include the Mazak HCN5000, notable for its 18,000 rpm high-speed spindle and 4-axis capability, and the Nakamura Tome AS-200, with its 12-position turret and ability to be live tooled. Given the precision required in medical manufacturing, we perform comprehensive inspections using both visual methods and CMM technology. Our Zeiss CMM Contura G2 and RAM Optical Starlite 150 vision systems are integral to these processes. Our ISO 9001:2015 certification is a testament to our unwavering commitment to quality.

Call (978) 486-9626 or email info@plmachine.com to start working with the premier machine shop for the biotech and medical device industry in Massachusetts.

CNC Turning Services

CNC Milling Services