Machine Shop for the Biotech and Medical Device Industry

When it comes to manufacturing for healthcare and scientific applications, precision is paramount. At P&L Machine we specialize in providing CNC machining solutions for the biotechnology and medical device industries. Our years of experience and advanced equipment is evident in every detail of our finished work. Individuals and organizations in Massachusetts, throughout New England and across the USA rely on us to deliver consistently accurate and high-quality components as well as full builds, including intricate surgical instruments, test lab equipment, medical device prototypes and more.

Call or email us to begin exploring options for your project with a member of our team.

Helping Shape the Future of Science and Medicine

Versatility has helped position us as the go-to machine shop for the biotech and medical device industries. No matter what your specific application may be, we have the human, machine and material resources required to efficiently bring your concept to life. Whether you need components comprised of medical-grade metal, plastic, ceramic, composite or polymer – our team has you covered. From compact components to full-size parts and complete medical instrument assemblies, we are equipped to handle projects of every scale and level of technical complexity.

Precision in Every Part

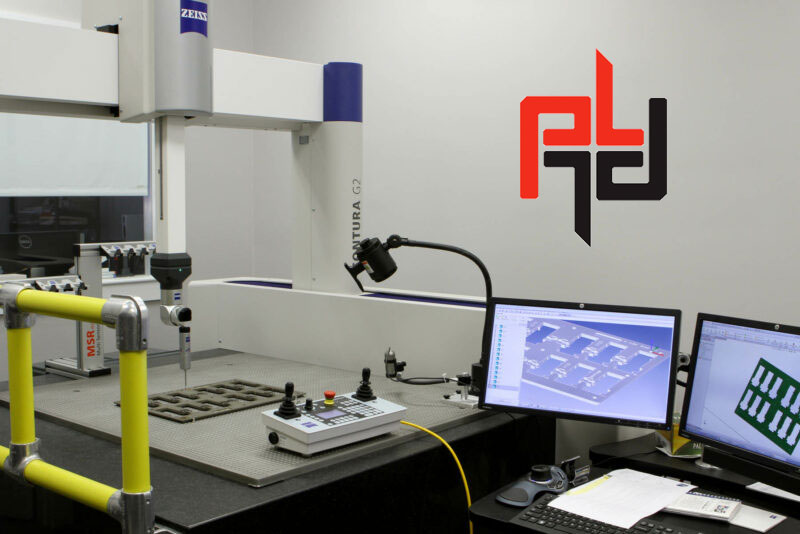

Our fleet of state-of-the-art CNC milling and turning centers are integral to our machine shop’s ability to serve clients in biotech and medical devices. One machine worth highlighting is our Mazak HCN5000, which features a high-speed 18,000 rpm spindle and 4-axes. Another is our Nakamura Tome AS-200 that boasts an impressive 12-position turret and live tooling capabilities. Because there is no margin for error in medicine or healthcare related applications, we painstakingly check our work with visual and CMM inspections. Our Zeiss CMM Contura G2 and RAM Optical Starlite 150 Vision system are indispensable for these tasks.

Call (978) 486-9626 or email info@plmachine.com to start working with the premier machine shop for the biotech and medical device industry.

CNC Turning Services

CNC Milling Services