Machine Shop for the Aerospace and Defense Industry

P&L Machine is the premier machine shop serving the aerospace and defense industry. We understand that every micron matters in manufacturing for these fields, and even the smallest errors simply won’t fly. Our team of dedicated professionals combines cutting-edge technology with unparalleled expertise to produce components for passenger aircraft, unmanned aerial vehicles (UAV) and more that meet or exceed compliance requirements as well as the expectations of our valued clients in Massachusetts, New England and across the USA. Whether you’re in the prototyping phase or you’re ready for a light-out production run, you can count on us to deliver quality results with exceptional accuracy.

Call or email us to begin exploring options for your project with a member of our team.

The Sky is the Limit for Your Manufacturing Project

We take pride in taking on CNC machining projects for the aerospace and defense industry of diverse sizes and technical complexity – from large components for various housings to compact pieces for secondary systems and more. Our manufacturing expertise encompasses a wide variety of cutting-edge materials, including aerospace-grade aluminum, titanium and stainless steel as well as advanced composites like carbon fiber-reinforced polymers (CFRP) and polyether ether ketone (PEEK). We source from trusted suppliers to ensure your components withstand the extreme temperatures, pressures and stresses that they are designed to.

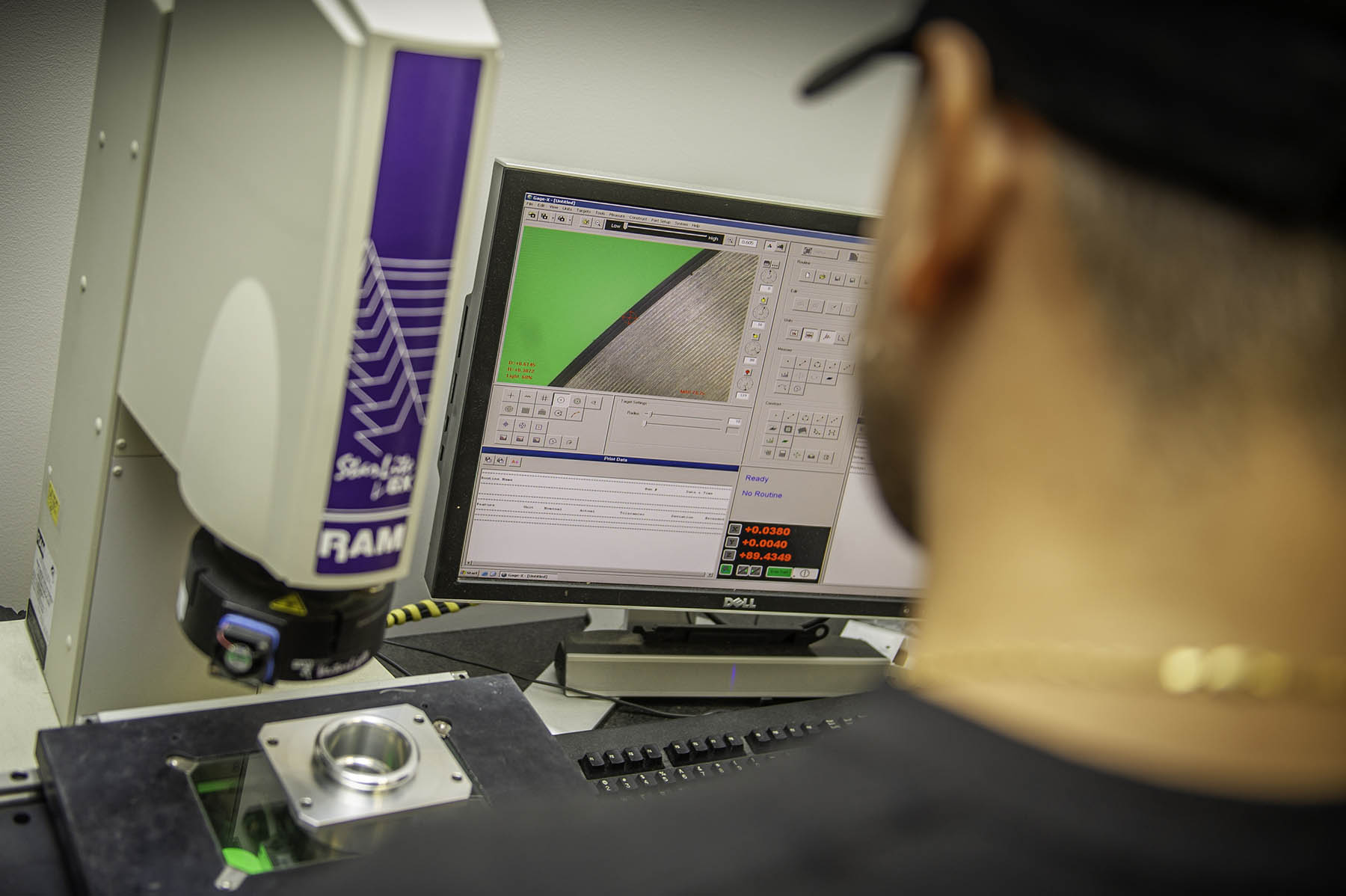

Precision and Quality from Spindle to Inspection

Our ability to effectively serve clients in aerospace and defense is built on a foundation of state-of-the-art CNC equipment. For instance, the Mazak HCN5000 features a high-speed 18,000 rpm spindle and 4-axes is ideal for precision milling applications. Another machine worth mentioning is our Nakamura Tome AS-200, with live tooling capabilities and 12-position turret for CNC drilling. Given the often life or death nature of aviation and military work, we carry out a painstaking quality check process with CMM inspections facilitated by our Zeiss CMM Contura G2 and RAM Optical Starlite 150 systems. You can take additional confidence in our ISO 9001:2015 certification status.

Call (978) 486-9626 or email info@plmachine.com to start working with the premier machine shop for the aerospace and defense industry.

Cutting Edge Tools and Technology of the Trade

Our ever-growing and expanding collection of specialized technology and equipment allows us to effectively meet every aspect of your unique requests.

Precision CNC Turning Machining Services

If your project requires rotational symmetry, the most cost and time effective way to produce it is likely through our CNC turning capabilities. Bolts, screws, pins and other cylindrical components are perfect for this machining technique. CNC turning is facilitated with preprogramed CNC lathes. Because this equipment is less complex than CNC milling systems with multiple axis — it can often be utilized at a lower expense.

Features of our precision CNC turning machining services include:

Precision Horizontal Milling Services

Creating more intricate parts can be affectively accomplished with our horizontal CNC milling machines. These systems perform material reduction on multiple axis with exceptional precision. Our collection of CNC equipment includes both 3 axis and 4 axis milling machines.

Features of our precision CNC turning machining services include:

“Integrity of product and performance is the key to their success and has become the standard against which we gauge all others.”

“We greatly value our relationship with P&L Machine. You are our GO-TO vendor when we have a tough or timely issue to deal with. We appreciate your willingness to work with us.”

“P&L is easy to deal with and delivers good quality work all the time.”

“I really enjoy doing business with P&L.”