Aerospace Machine Shop in New Hampshire

In the aerospace industry, precision is paramount. The slightest error in any component could be disastrous – from critical turbine blades, exhaust nozzles and thrust reversers to interfacing elements like control yokes, throttles, rudder pedals and more. With this in mind, aerospace engineers, manufacturers and maintenance personnel in New Hampshire and beyond that need a reliable aerospace machine shop choose to work with our team at P&L Machine. Our state-of-the-art machining techniques deliver precision results for every project, regardless of variable factors like size, technical complexity, required materials and more.

Call or email us to begin exploring options for your project with a member of our team.

Where Innovation Takes Flight

If you are searching for a machining company serving New Hampshire that can create flawless components for your commercial airline or defense vehicle project, look no further. Our aerospace machine shop in Littleton, Massachusetts is equipped with the latest CNC mills, lathes and other machinery, as well as industry-leading software, including MasterCam, SolidWorks and Vericut. For example, the Mazak HCN5000, 4 Axis Horizontal Machining Center, Fanuc Robodrill A-D21MiB5 and Proto Trac DPM – V3 are just a few of the advanced apparatus we use for milling applications. When it comes to turning, we have a Hardinge Talent 8/52 – SV Turning Center, Hardinge Manual Tool Room Lathe, Feeler FTC-200L Turning Center and multiple Nakamura Tome AS-200’s on hand.

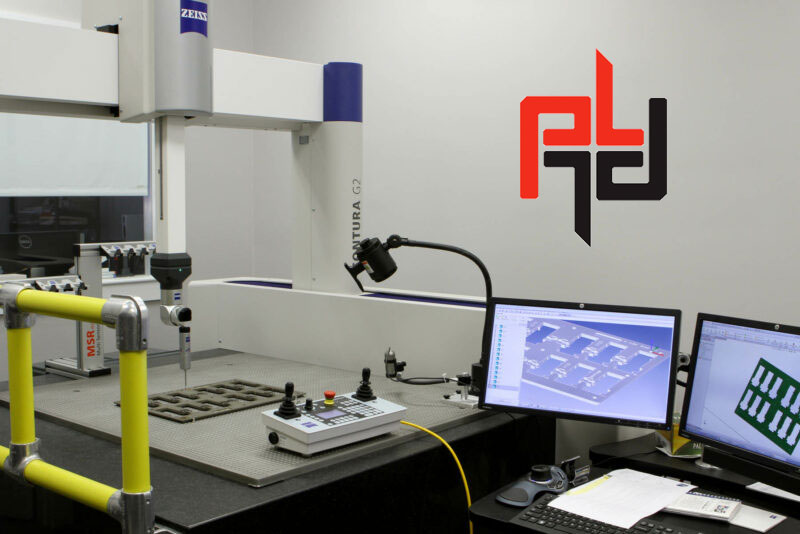

Propelling Excellence

We provide comprehensive manufacturing services, from prototyping and trial runs to lights-out production with sub-assembly and more. Our quality assurance framework consists of both intensive visual checks as well as the use of coordinate measuring machines (CMM) to ensure your project’s exact specifications are met. We facilitate automated inspections using our Zeiss CMM Contra G2 and the RAM Optical Starlite 150 Vision System. Project documentation, such as statistical and historical process control information, is also meticulously scrutinized. Additionally, we uphold ISO 9001:2015 certification – so you can be confident that your components meet regulatory compliance standards.

Call 978-486-9626, email info@plmachine.com or send us a message through the form here on our website to get started on your project with our team today.

CNC Turning Services

CNC Milling Services