Aerospace Machine Shop in Massachusetts

In the aerospace field, the margin for error is non-existent. From the turbine blades, exhaust nozzles, heat exchanges and other engine components to passenger seats, overhead storage bins, cabin ventilation systems and other interior parts – every piece must be flawless for safe and reliable operation to take place. That is why when aviation engineers, manufacturers, maintenance specialists and others in the field need an aerospace machine shop in Massachusetts, New Hampshire, Connecticut or elsewhere across United States, they rely on our team at P&L Machine. Our elite machining techniques ensure that your project is executed with precision – regardless of its scale, the materials used, specific application or any other variables.

Call or email us to begin exploring options for your project with a member of our team.

P&L Machine: Where Your Ideas Take Off

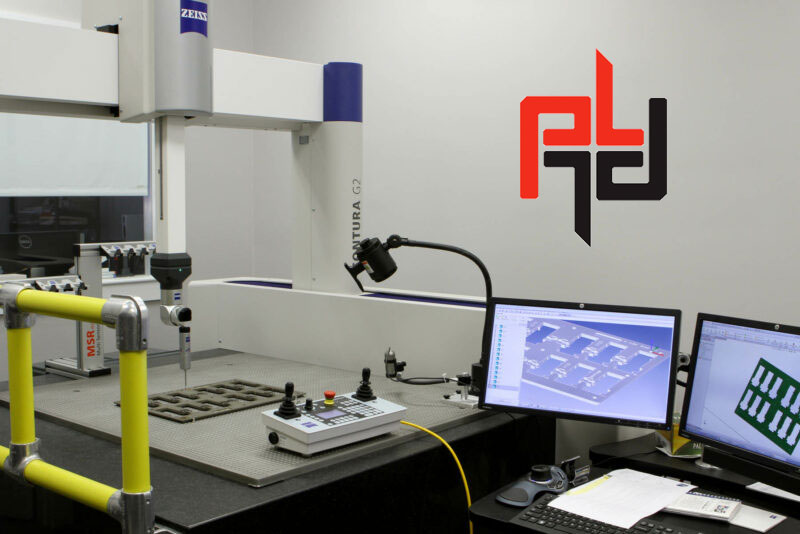

Our aerospace machine shop in Massachusetts is at the forefront of innovation, creating components for next-generation commercial airliners, defense vehicles and more. We’ve outfitted our facility with state-of-the-art CNC mills and lathes, along with advanced design software like MasterCam, SolidWorks and Vericut. Our Mazak HCN5000 4 Axis Horizontal Machining Center is integral in producing the precision-engineered parts, thanks to its high-speed 18,000 rpm spindle. Additionally, the Fanuc Robodrill series, with its DDR 4th axis trunnion table, is an indispensable tool for machining complex components. For precision turning, we rely on the Nakamura Tome AS-200, Hardinge Talent 8/52-SV and Feeler FTC-200L Turning Center.

A Turbulence-Free Production Process from Start to Finish

From the moment you engage with P&L Machine, you’ll notice our commitment to excellence. We cater to all phases of production, from the earliest stages of prototyping to full-scale manufacturing runs. Our dual-pronged quality assurance strategy employs both automated measurement systems and meticulous visual inspections to ensure your project is up to specification. Instruments like the Zeiss CMM Contura G2 and RAM Optical Starlite 150 Vision System are integral to our error-free production. For complete transparency, we provide detailed documentation, including historical and statistical process control data. Our certification in ISO 9001:2015 is more than just a formality. This designation represents our dedication to industry-leading standards and compliance.

Contact us to get started today. Call 978-486-9626, email info@plmachine.com or send us a message through the form here on our website.

CNC Turning Services

CNC Milling Services