Aerospace Machine Shop Serving Connecticut

Aerospace engineers, manufacturers, purchasers and many others rely on our team at P&L Machine when they need a reliable aerospace machine shop serving Connecticut and the surrounding area. In this field, having a margin for error simply doesn’t fly. Aerospace professionals count on us to make sure every detail of each component flawlessly meets your predetermined specifications. The ability to effectively take on aerospace projects of varying size, technical parameters and material requirements is a point of pride for our team.

Call or email us to begin exploring options for your project with a member of our team.

The Sky is the Limit for Your Project

Whether your Connecticut company has a project involving commercial airliners, defense vehicles or anything in between we have you covered. Conveniently located in Littleton, Massachusetts, our aerospace machine shop is outfitted with the latest tech. Our CNC mills, lathes and other advanced machinery run on best-in-class software, including MasterCam, SolidWorks and Vericut. For turning operations, we rely on precision instruments like the Hardinge Talent 8/52 – SV Turning Center, Hardinge Manual Tool Room Lathe, Feeler FTC-200L Turning Center and Nakamura Tome AS-200. Among our suite of milling equipment are top-tier machines including the Mazak HCN5000, 4 Axis Horizontal Machining Center, Fanuc Robodrill A-D21MiB5 and Proto Trac DPM – V3.

Our inventory management system allows us to support both Kanban and consignment methods of inventory management. Our ERP system keeps track of part inventory levels to ensure that we have sufficient product available to always meet your needs.

Elevating Aerospace Manufacturing Standards

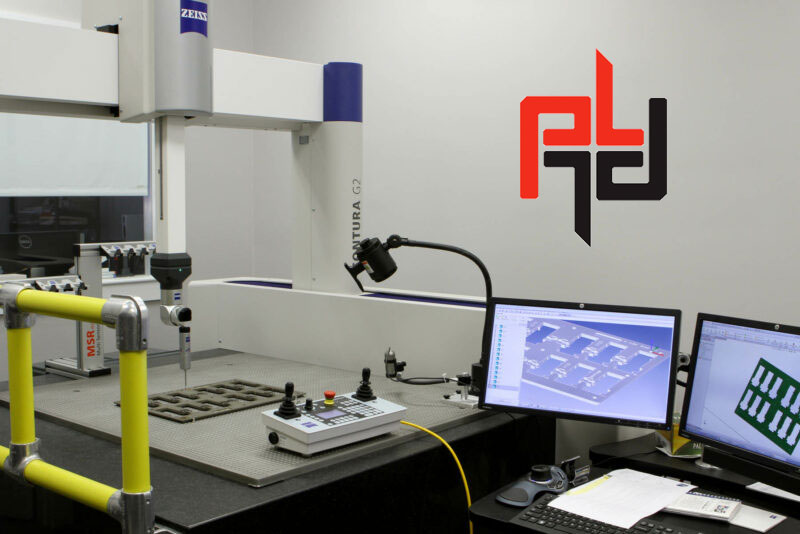

Our aerospace machining services cover prototyping and trial runs with seamless integration into lights-out production, sub-assembly and beyond. To ensure quality, we make thorough visual inspections as well as use advanced coordinate measuring machines (CMM). Our Zeiss CMM Contra G2 and RAM Optical Starlite 150 Vision System enable us to conduct these CMM inspections with complete accuracy. We also review project documentation, including statistical and historical process control data, to uphold our stringent standards. Our commitment to best practices and regulatory compliance is reflected in our ISO 9001:2015 certification status.

Call 978-486-9626, email info@plmachine.com or send us a message through the form here on our website to get started on your aerospace machining project with our team today.

CNC Turning Services

CNC Milling Services